Invented by Aharon Meir Eyal, Robert P. Jansen, Revital Mali, Asher Vitner, Virdia Ltd, Virdia LLC

Sugar mixtures are blends of different types of sugars, such as white sugar, brown sugar, powdered sugar, and syrups, which are used in various applications. These mixtures are created to enhance the taste, texture, and functionality of food and beverage products. They are widely used in baking, confectionery, dairy, beverages, and other food processing industries.

One of the key factors driving the market for sugar mixtures is the growing consumer preference for natural and healthier alternatives to traditional sugar. Sugar mixtures offer a way to reduce the overall sugar content in products while maintaining the desired sweetness. This is particularly important as consumers become more health-conscious and seek products with reduced sugar levels.

Moreover, sugar mixtures provide functional benefits to food and beverage manufacturers. They can improve the stability, shelf life, and texture of products, as well as enhance flavors and colors. For instance, sugar mixtures can prevent crystallization in confectionery products, improve the mouthfeel of ice creams, and act as a bulking agent in baked goods.

In terms of production methods, there are several techniques employed to create sugar mixtures. One common method is blending different types of sugars in specific ratios to achieve the desired taste and functionality. Manufacturers may also use specialized equipment, such as mixers or homogenizers, to ensure a uniform mixture.

Another method involves the use of sugar substitutes, such as artificial sweeteners or natural sweeteners like stevia or monk fruit extract, in combination with traditional sugars. This allows for the creation of low-calorie or sugar-free sugar mixtures, catering to the needs of consumers who are looking for healthier options.

The use of sugar mixtures extends beyond the food and beverage industry. They are also utilized in pharmaceuticals, cosmetics, and personal care products. In pharmaceuticals, sugar mixtures are used as excipients in tablets and capsules to improve taste and aid in drug delivery. In cosmetics, they can act as moisturizers or humectants, providing hydration to the skin.

As the market for sugar mixtures continues to grow, manufacturers are investing in research and development to create innovative products. They are exploring new combinations of sugars, as well as incorporating natural additives like fruit extracts or spices to enhance flavors. Additionally, there is a focus on developing sustainable and eco-friendly production methods, such as utilizing renewable energy sources or reducing water usage.

In conclusion, the market for sugar mixtures and methods for production and use thereof is experiencing steady growth due to the increasing demand for healthier and functional food and beverage products. With advancements in production techniques and a focus on innovation, this market is expected to expand further in the coming years. Manufacturers and suppliers in this sector have the opportunity to tap into this growing market by offering a wide range of sugar mixtures that cater to the evolving needs of consumers.

The Virdia Ltd, Virdia LLC invention works as follows

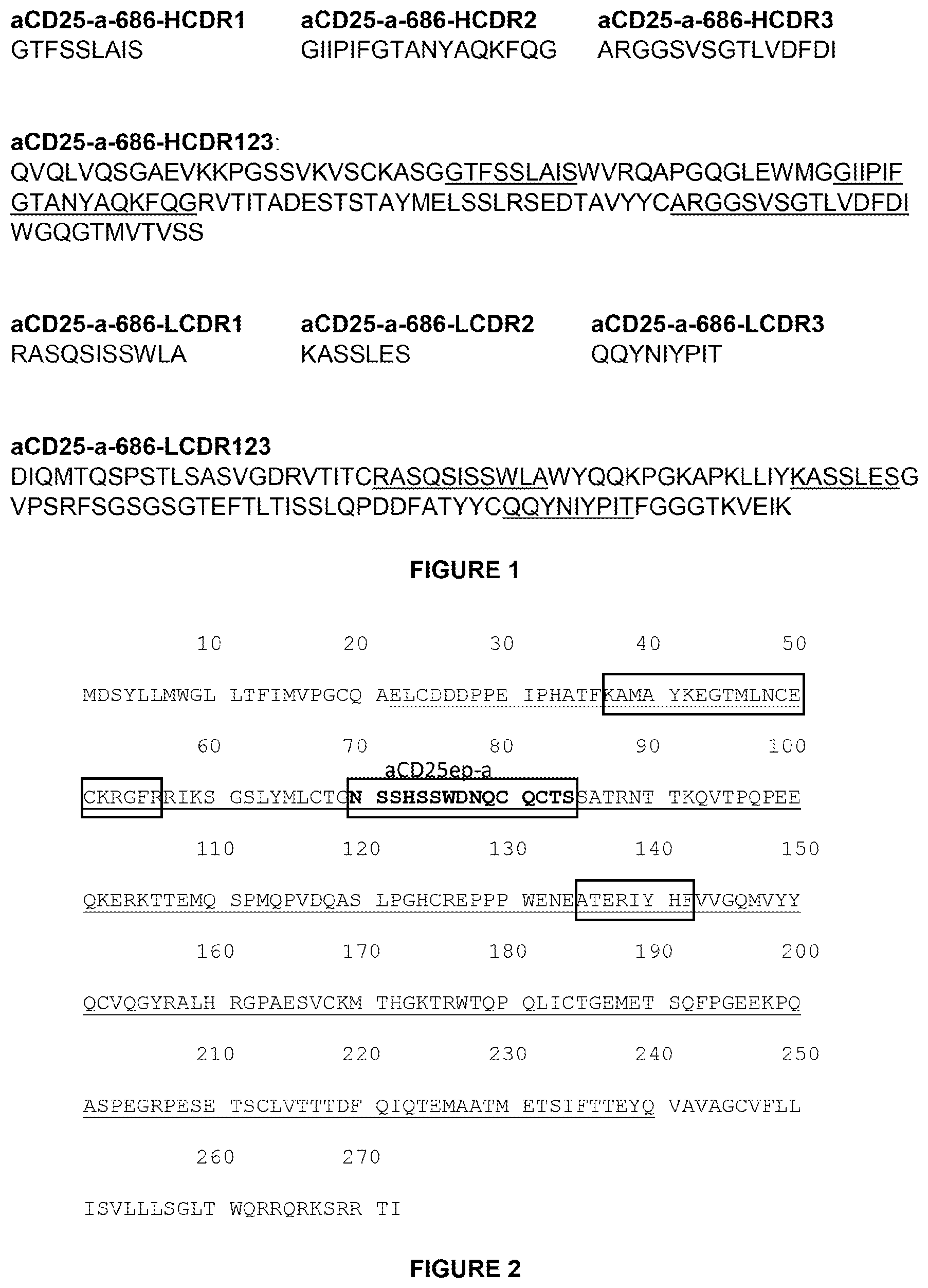

A sugar mixture containing: monosaccharides, oligosaccharides at a proportion of 0.06 to the total saccharides, disaccharides at a proportion of 0.05 to the total saccharides, pentose at a fraction of 0.05 to the total saccharides and at least alpha-bonded diglucose. The methods for making and/or using such mixtures are also disclosed.

Background for Sugar Mixtures and Methods for Production and Use thereof

The carbohydrate-conversion industry is large and rapidly increasing in size. About 100 million tons are fermented each year, primarily for fuel-grade alcohol. It is expected that this number will triple within the next decade.

Millions tons of carbohydrates, including citric acid and Lysine, are fermented each year to produce food and feed products. Fermentation is also increasing in volume and intensity to produce monomers, for example, which are used by the polymer industry. “Lactic acid is used to produce polylactide.

Fermentation media usually include other nutrients, such as minerals, vitamins and growth factors, along with carbohydrates or another carbon source. In certain cases, fermentation media contain well-identified chemicals. Other times, different preparations are used (e.g. In other cases, different preparations (e.g. Some of these preparations are derived from natural sources such as extracts. Some of these preparations are relatively expensive.

With the advent of molecular biological techniques, a whole new generation of industrial fermenting, or conversion, is based on genetically modified microorganisms. These microorganisms can rely on inducible promoters to induce a particular gene. Some inducible promoters are activated by specific sugars.

The industrial application of these technologies is still a challenge. The hydrolysis of hemicellulose can be relatively simple, but the hydrolysis of cellulose is difficult because of its partial crystal structure.

This application is a review of the Hoy’s cohesion parameters Delta-P or Delta-H.

Delta-P is a component related to polarity of Hoy?s cohesion parameters and delta-H the component related to hydrogen bonds of Hoy?s cohesion parameters.

Hildebrand defined the cohesion parameter (or solubility parameter) as the square root the cohesive energy densities:

?\n=\n?\n?\n?\nE\nvap\nV\n\nwhere ?Evap and V are the energy or heat of vaporization and molar volume of the liquid, respectively. Hansen extended Hildebrand’s original parameter into a three-dimensional parameter of cohesion. This concept separates the total solubility, delta, into three components or partial solubility coefficients relating to specific intermolecular interaction:n?2=d 2+p 2+h 2nwhere delta-D is the dispersion component, delta-P the polarity component, and delta-H the Hydrogen bonding component. Hoy developed a method to estimate partial and total solubility. These parameters are measured in MPa1/2. The CRC Handbook of Solubility Parameters & Other Cohesion Parameters, 2nd edition, pages 122-138, provides a detailed explanation of this parameter and its component parts. This and other references contain tables that list the parameters of many compounds. The methods to calculate these parameters are also provided.

An aspect of certain embodiments of the present invention relates heterogeneous mixtures of sugar. The term “sugar” is used. As used in the specification and accompanying claims, monosaccharides/oligosaccharides are defined as those that are soluble in 25 degree centigrade water. In this application, disaccharide is used to refer to sugar dimers or?higher-oligosaccharides’. or ?higher saccharide? Refers to oligomers that contain three or more units of sugar. Dimers can be homo-dimers or hetero-dimers according to different exemplary embodiments. “Alternatively or additionally higher oligosaccharides can include the same sugar unit and/or a different one.

In many of the exemplary embodiments, the sugar mixtures are the result of acid hydrolysis from lignocellulosic (or “woody”? substrates. In certain exemplary embodiments, the acid hydrolysis with HCl is carried out, optionally, at a concentration equivalent to 37% W/W HCl/[HCl+water], or optionally, 39, 41, 42, or even 45% HCl. In some embodiments, hydrolysis can be conducted at temperatures lower than 50 degrees centigrade. This could include below 40 degrees, below 30 degrees or even 25 degrees. In some exemplary inventions, a portion of hydrolysis takes place at temperatures of 20 degrees centigrade or lower, or 15 degrees.

Accordingly to various exemplary manifestations of the invention, the sugar mixture is supplied as a liquid or syrup. Optionally, residual acid from the hydrolysis can be included. The total sugar concentration in a syrup/liquid may be as high as 50% or even higher. The mixture can be provided as crystals or dry powder.

In some exemplary embodiments, the percentage of oligosaccharides in the mixture to the total saccharides is higher than 4, optionally 6 or 8, optionally 10 or 15% or even greater.

In some exemplary embodiments, the percentage of total saccharides to disaccharides in the mixture may be greater than 3. Optionally 5, optionally 7. Optionally 10% or higher percentages.

?Disaccharide? “?Disaccharide? indicates two sugars linked by an alpha or beta bond, or bonded by various hydroxyls in the molecule.

In some exemplary embodiments, the percentage of pentoses in the total mixture of saccharides is higher than 3. Optionally 5, optionally 7. Optionally 10% or even greater percentages. Optionally, a portion or all of the pentose can be present in a longer oligosaccharide.

According to different exemplary embodiments, the mixture contains at least one di-glucose with an alpha bond and/or one di-glucose with a beta bond. Optionally, a portion of di-glucoses can be present in higher oligosaccharides.

In some exemplary embodiments, residual acid (e.g. The mixture may contain HCl. The invention includes several exemplary embodiments that deal with the removal of this residual acid. This removal can also add value to downstream processes. fermentation). In certain exemplary embodiments, the removal of residual acids involves extraction using an extractant that contains alcohol. Two or more extractions can be conducted. In certain exemplary embodiments, at least one extraction uses a combination of two solvent types.

Another feature of certain embodiments of the present invention is the hydrolysis of a lignocellulosic material in HCl, resulting in a hydrolyzate containing total saccharides (total saccharides+water), of at least 20 percent, optionally 25 percent, or optionally 30 per cent by weight, and the de-acidification of the hydrolyzate, while increasing its sugar concentration. The sugar concentration can be increased to 35-40-45-50 or higher or intermediate percentages. In certain exemplary embodiments, the disaccharides are at least 5% of the total saccharides, or a higher percentage. Optionally, some of the saccharides can be digested enzymatically.

Another embodiment of the invention involves fermenting a sugar mix in a fermentation vessel to produce a desired conversion product or fermentation product.” The fermentation product may include alcohols, carboxylic acid, amino acids or monomers to produce industrially important polymers. In certain exemplary embodiments, the fermentation product (e.g. The 3-hydroxy-propionic acids will be converted to acrylic acid and then polymerized. In some exemplary embodiments, the monomer can be produced directly. “Lactic acid as a polylactide source”.

Optionally the proteins are heterologous protein produced by genetically altered microorganisms. These heterologous protein include hormones, enzymes such as (e.g. Cellulases, growth factors, cytokines, and antibodies are all examples of heterologous proteins. The antibodies can be fusion proteins that include a non immunoglobulin domain.

Click here to view the patent on Google Patents.